How To Make FECO

Baboo's Approach

With this approach, about 5 grams FECO per ounce of cannabis can be expected, which is about an 18% yield. If the quantity of FECO produced is significantly lower, then there was likely some loss during the process. If it is significantly higher, there is likely too much residual solvent left. Here are some videos that better explain this process.

Watch Video 1>

Watch Video 2>

The information provided here is for educational purposes only and is not intended as medical or professional advice. If you choose to use these methods, please ensure you take necessary precautions, including wearing protective gear and working in a well-ventilated area. Always prioritize safety when handling flammable substances.

Materials Needed

- Cannabis

- 190-proof ethanol (Everclear or organic grain alcohol)

- Oven

- Metal baking pan

- Aluminum foil

- Plastic gloves

- Electric grinder

- Infusion machine (Infuzium 420, Infusion Buds, or Magical Butter machine)

- Stainless steel pan

- Stand for putting inside the steel pan

- Micron filter bag

- 2 Funnels

- Glass or BPA-free plastic container

- Thick paper towels

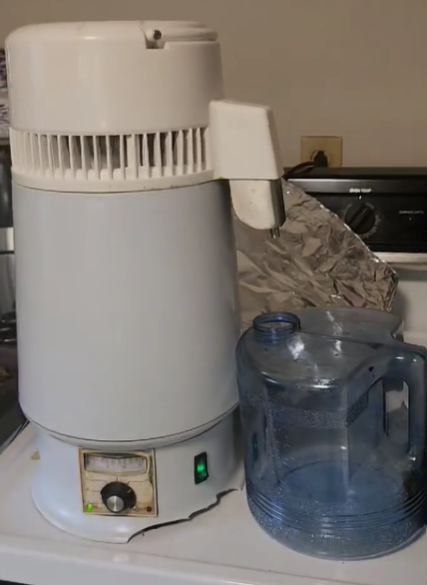

- Countertop distiller

- BPA-free plastic jug

- Spatula

- Oral syringe

Step by Step Process

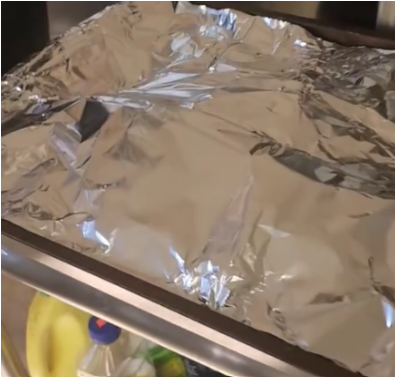

Step 1: Put the cannabis in a metal pan and cover with aluminum foil. Place in oven at 225F for 45 minutes to 1 hour. This decarboxylates the cannabis, changing THCA to THC. The cannabis will turn from green to brown during this process.

Step 2: Grind the cannabis in an electric grinder to a very fine level

Step 3: Place the cannabis into an infusion machine like the Infuzium 420, Infusion Buds, or Magical Butter machine. Cover with food-grade ethanol (such as 190 proof Everclear or some kind of organic grain ethanol) up to the ridge line and heat at 160F for 4 hours. The solution will turn dark during this process.

Step 4: Prepare for filtration with your stainless steel pan, stand, and filter bag (anything between 75-200 microns is fine). The stand goes inside the pan and is used to hold up the filter bag. Unplug whatever infusion machine you are using, and stir the mixture with a spatula before pouring the contents through the filter. The spatula can be further used to help get nearly everything out. If a small amount remains, some more ethanol can be poured into the container, swished around, then poured into the filter

Step 5: Allow the solution to filter through the bag. The solid cannabis material is left behind in the bag. At this point, virtually all of the beneficial compounds in the cannabis have been extracted into the ethanol. Once about half of the solution has filtered, pour some more ethanol over the mixture to facilitate the filtration process. This may increase yield by up to 20%.

Note: The process can be done on the table or the floor. The extractor recommends the floor because spillage sometimes occurs and can stain tables.

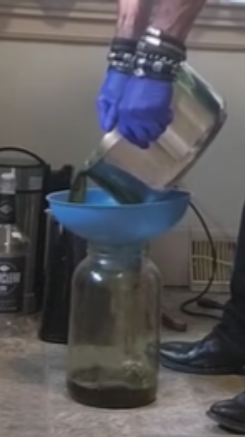

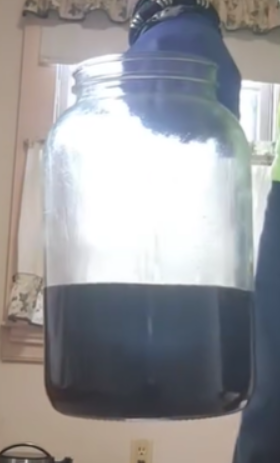

Step 6: Pour the solution through a funnel into a glass or BPA-free plastic container. The plastic containers will not break if knocked into something. They are fine for short-term use, but tincture or FECO should not be stored long-term in plastic. Pour towards the front of the funnel to minimize the potential for loss.

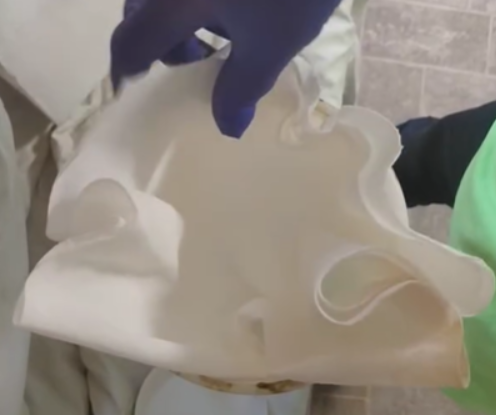

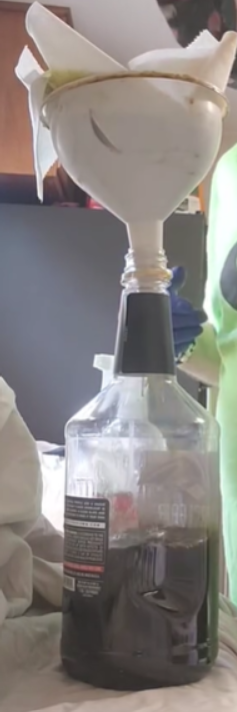

Step 7: This is the second filtration step. The solution can be filtered back into the ethanol bottle (in this case, Everclear) by pouring over a thick paper towel put over a funnel. Make sure you are using thick, high-quality paper towels. Take 3 sheets, fold them in half, put them over the funnel, and gently push them in. Keep the sides of the paper towels facing up. The solution can then be poured through. Since it takes time to filter, the entire solution can’t be poured in at once and must be done in stages.

The process should be repeated at least once, and ideally twice, to ensure full removal of all plant matter. By having two bottles and two funnels, it is easy to pour from one into the other.

This step is important because residual plant matter in FECO can cause it to clog up and be harder to squeeze out.

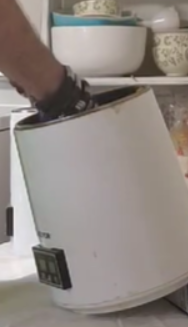

Step 8: our the solution into a countertop distiller. This will evaporate out the ethanol and allow you to reclaim it in a container, like a jug as shown.

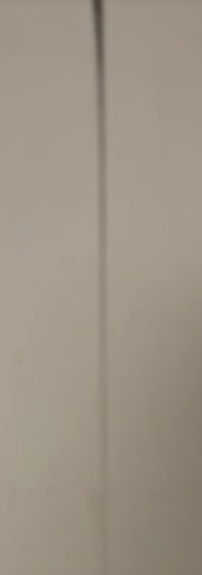

Step 9: It is critical to determine the FECO is finished and doesn’t have much residual ethanol. If the FECO drips down with semi-thick strings of 4 to 6 inches, as shown below, that means there is still too much residual solvent and more heating is needed. It is important to let the FECO cool before doing this test, as finished FECO, when warm, may still show these strings.

FECO is finished when the strings are around 12 inches long and much thinner.

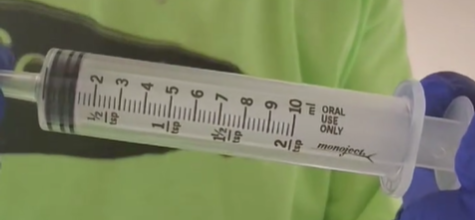

Step 10: Once the FECO is finished, it can be put in oral syringes. To facilitate this, lifting up the distiller at an angle by placing a small box under it is effective. The distiller should be turned back on at a low heat, about 60-80F, which lowers the viscosity of the FECO so it can be syringed. Within just about a minute, it will be warm enough to syringe.

Pull a little FECO up into the syringe by pulling the plunger back. Then push the FECO back out, which is important for clearing out all air. Be sure to put the tip of the syringe in only as far as it needs to go, submerging the whole tip is needlessly messy. After syringing, put the syringe slightly up at an angle as it cools. Having it horizontal or on a decline will lead to leaking. The syringe can then be capped.

Step 11: Keep the FECO syringes in a cool, dark place. If it becomes too solid to dispense, you can submerge the syringe in warm water (not going above the plunger area and with the cap on) to loosen it up.

Monojet 10mL syringe. 1 gram of FECO is equivalent to 1mL, so this would hold 10g of FECO